Just as you would survey the land and soil before building a home, offshore wind developers survey the seabed and geology in lease areas and along proposed cable routes, before building an offshore wind farm.

Installing offshore wind turbine foundations

Foundations are the structures that support offshore wind turbines in the water. There are different types of foundations such as jackets, monopiles, and even floating versions. Currently, our East Coast projects will use the fixed-bottom monopile foundations, which are suitable for shallow water.

To install monopile foundations, they’re first loaded onto an installation vessel which sails out to the wind farm site, stabilizing itself using dynamic positioning systems. An onboard monopile crane is used to lower the foundations into the sea, where they’re driven into the seabed using a hydraulic hammer.

This process emits sound underwater. To limit any potential negative impact on marine mammals and other species, we use noise reduction technologies, such as double bubble curtains, in addition to the above protective measures.

Bubble curtain systems are created by pushing pressurized air through small openings in a series of hoses. The result is a circular ‘curtain’ of bubbles around the monopile, which significantly dampens the sound pressure waves, reducing potential impacts on wildlife.

Installing offshore wind turbines

All components for the offshore wind turbines are brought out to sea in pieces to be assembled on site. Once in position, the installation vessel lowers its four legs onto the seabed to stabilize itself. Safety is always our top priority, so we only undertake these activities in appropriate weather conditions with detailed preparation, carefully testing the stability of each component before executing the next step.

We use a crane to place the steel turbine tower onto the foundation. The nacelle and rotor are then installed on top of the tower. Lastly, the blades are lifted and installed one by one by bolting them to the rotor.

Installing cables and the offshore substation

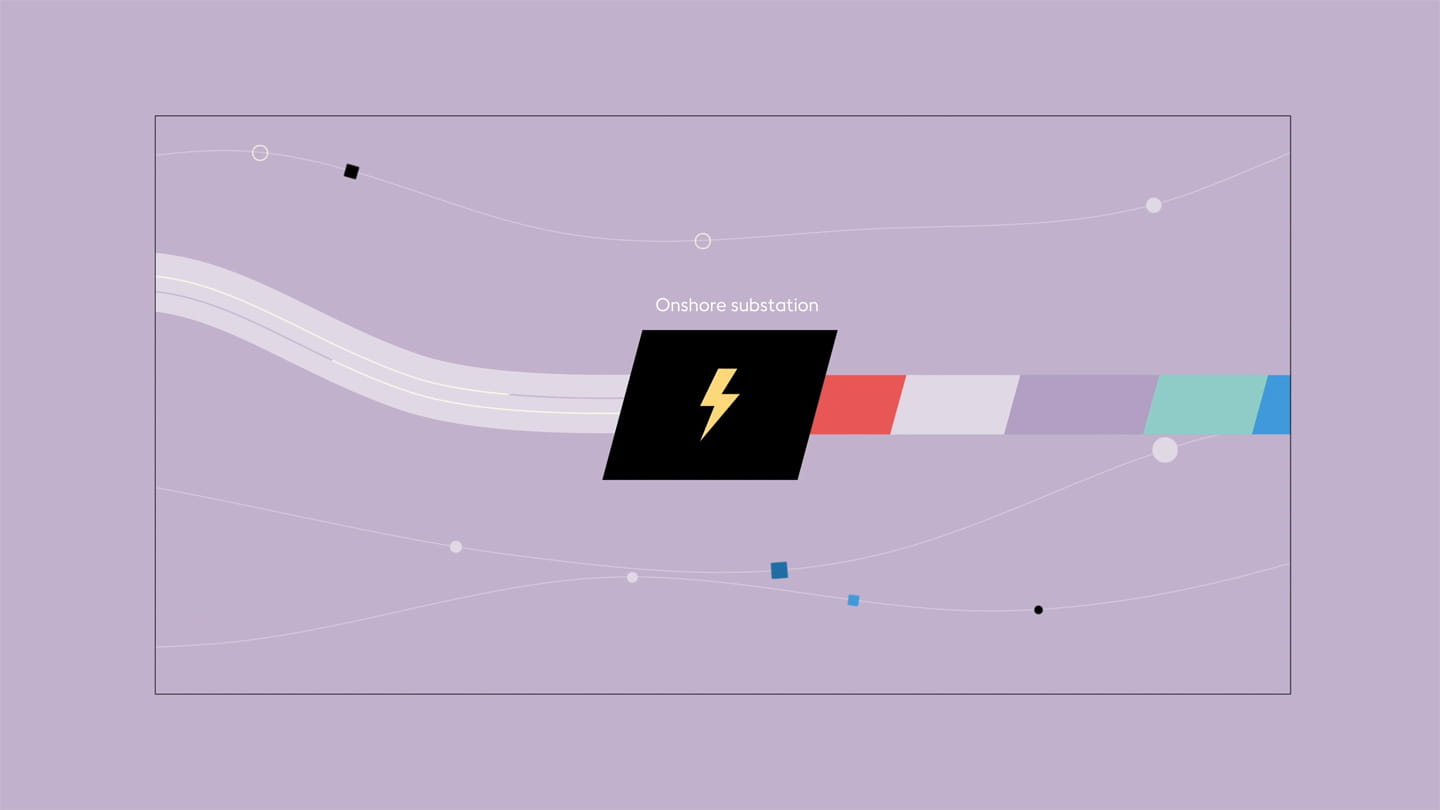

The offshore substation is located out at sea within the offshore project site. The substation collects the power generated by the turbines through inter-array cables, where it then transforms the power to a higher voltage and sends it to shore through an export cable. The export cable transports the power inland from the offshore substation– a process known as making landfall. Transmitting power at a higher voltage means that less energy is lost over the long distances it must travel.

An offshore substation consists of two parts: the foundation and the topside. The foundation is installed just like an offshore wind turbine foundation. The topside is constructed and tested onshore before being transported to the site to be placed on the foundation.

The cables themselves are also tested onshore for quality and performance before being installed onsite using a cable laying vessel. The vessel places the cables on to the seabed, connecting them to each turbine via the foundations. In addition, the exact location of the cables is also thoroughly researched prior to installation, to ensure we don't impact sensitive habitats.