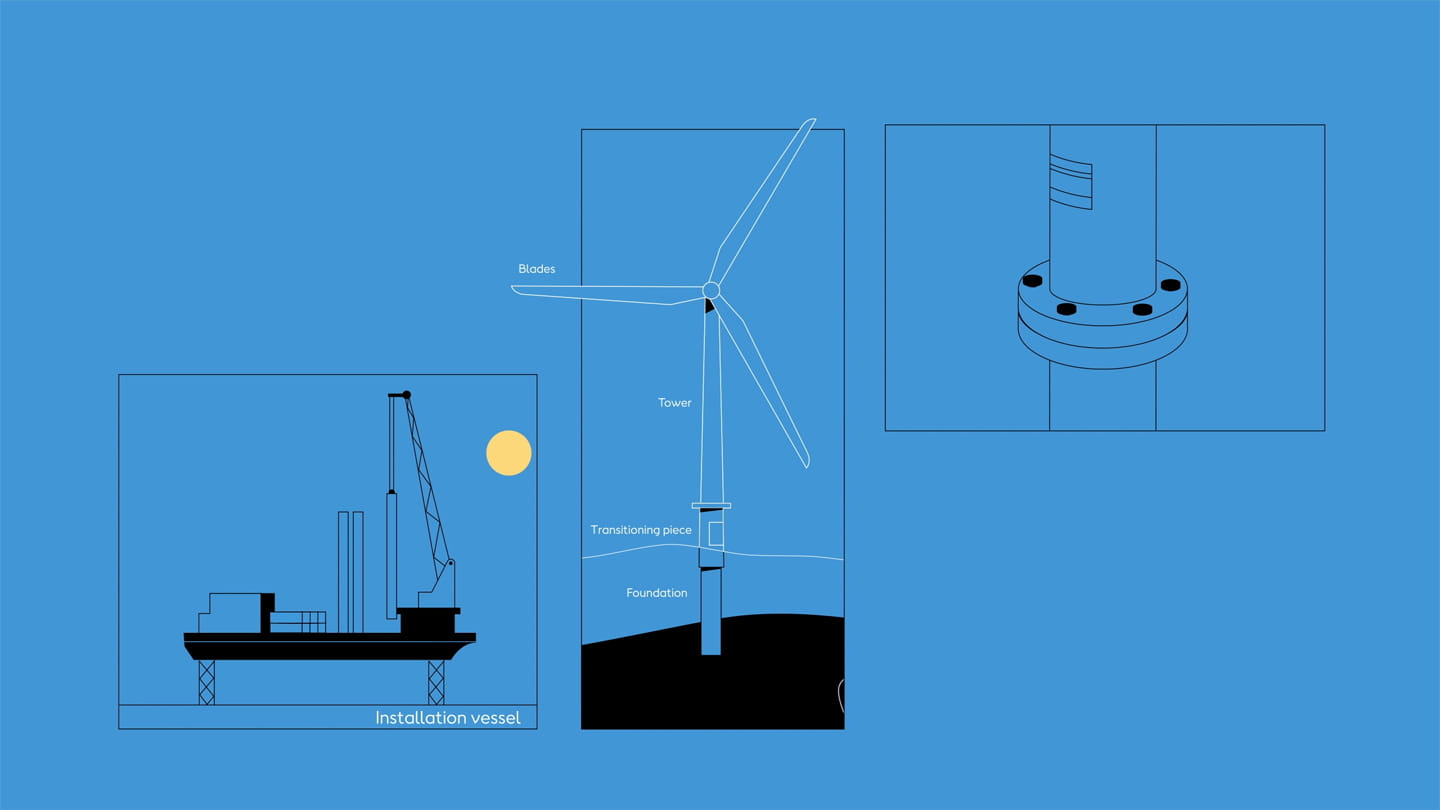

Constructing an offshore wind farm is a complex procedure: from choosing the right foundations, to shipping components to the site where they are installed, to ensuring we minimize our impact on the surrounding ecosystem.

Two of the most common types of pre-construction survey activities are geophysical and geotechnical surveys. Both surveys require a permit and approval from federal and/or state agencies based on location. While conducting offshore survey operations, we take the following protective measures:

Marine Species Protection

While conducting survey operations, all Ørsted-contracted survey vessels have trained observers onboard to watch for marine mammals and protected species 24 hours a day. Observers are equipped with visual technology, such as thermal imaging, that enhances detection ability, especially during periods of low visibility.

In compliance with regulations set by the National Marine Fisheries Service (NMFS), these observers actively look for whales, dolphins, other marine mammals, and protected species in the vicinity of the vessel. The observers direct the vessel to conduct an array of mitigation measures, where appropriate, to prevent impacts. This can include a reduction in vessel speed, change of course, or shutdown of the relevant sound sources.

We track and record all observations of marine mammals and protected species throughout our survey operations.

Additionally, survey vessels comply with seasonal and geographical vessel speed restrictions to minimize the risk of interactions with marine mammals.

Types of offshore survey work

Offshore geophysical surveys

We conduct high-resolution geophysical (HRG) surveys to map the seafloor and the geology beneath it, and to identify archaeological resources and debris left by other ocean users.

Equipment used during these surveys includes both acoustic equipment using varying frequencies of sound and passive sensors that do not emit sound. The sensors are either hull-mounted or towed above the seafloor behind the vessel. During HRG survey operations, vessels typically move at a low speed, between 2-4 knots (3-5 mph) transiting along straight survey lines.

Only a few HRG sources used in offshore wind surveys operate at frequencies detectable to marine mammals. Federal agencies have determined that no injury to marine mammals or protected species is expected from these HRG sources as the sound has been shown to diminish rapidly with distance (BOEM 2018).

The sources used in offshore wind that are detectable produce much lower energy and travel far shorter distances from the vessel than those used by the oil and gas industry for exploration miles below the seafloor.

The terms “seismic testing” and “seismic blasting” refer to powerful sound sources such as air guns used in oil and gas exploration. We don’t use these in HRG offshore wind surveys.

Offshore Geotechnical Site Investigations

Geotechnical Site Investigations (GTSIs) collect data from up to 200 feet below the seafloor to assess the mechanical behavior of soil and rock. We take measurements of soil properties, along with physical soil and rock samples, which we send for laboratory testing onshore. GTSIs do not produce any significant acoustic noise and therefore don’t pose a risk to marine mammals (BOEM 2021). While undertaking GTSIs, the vessel remains stationary on-site.